140001环境管理证书 中文

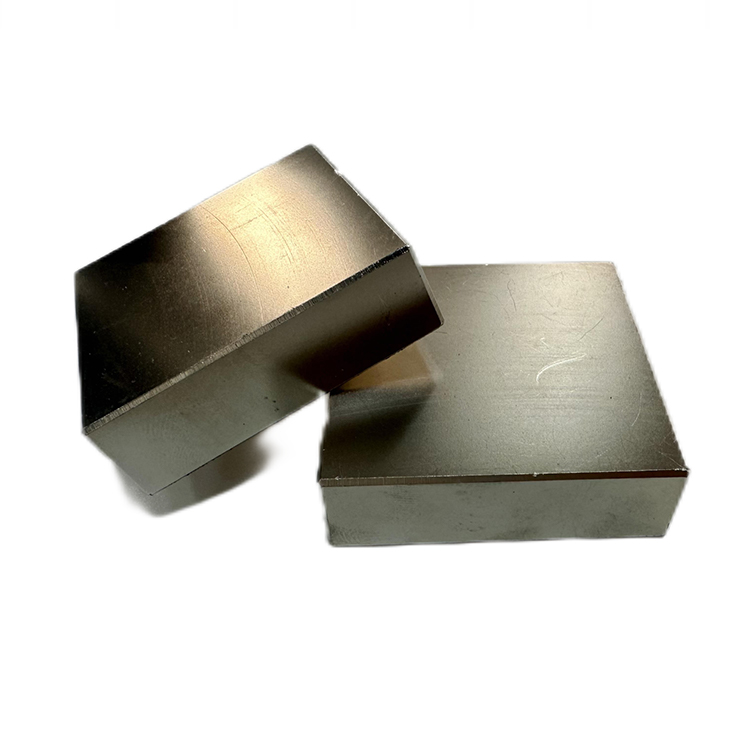

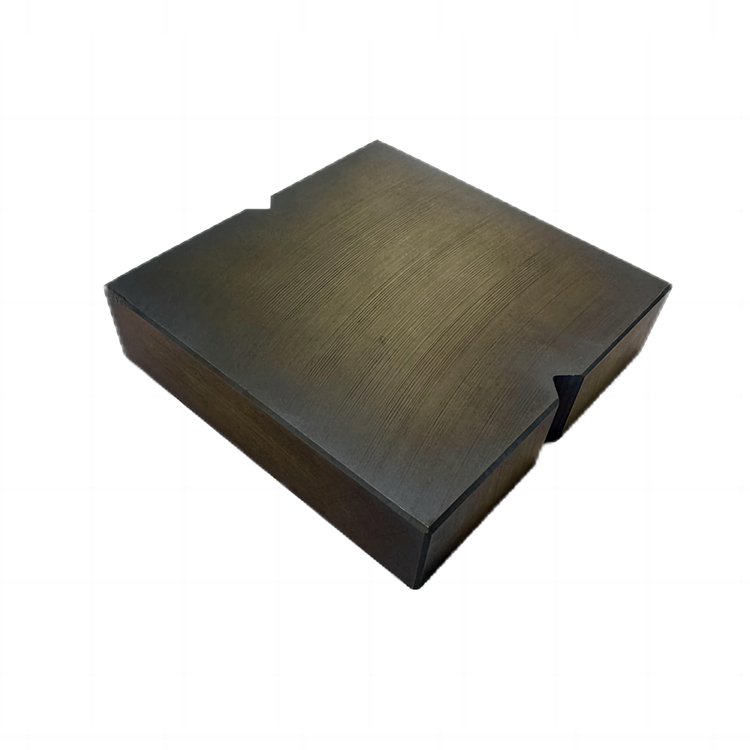

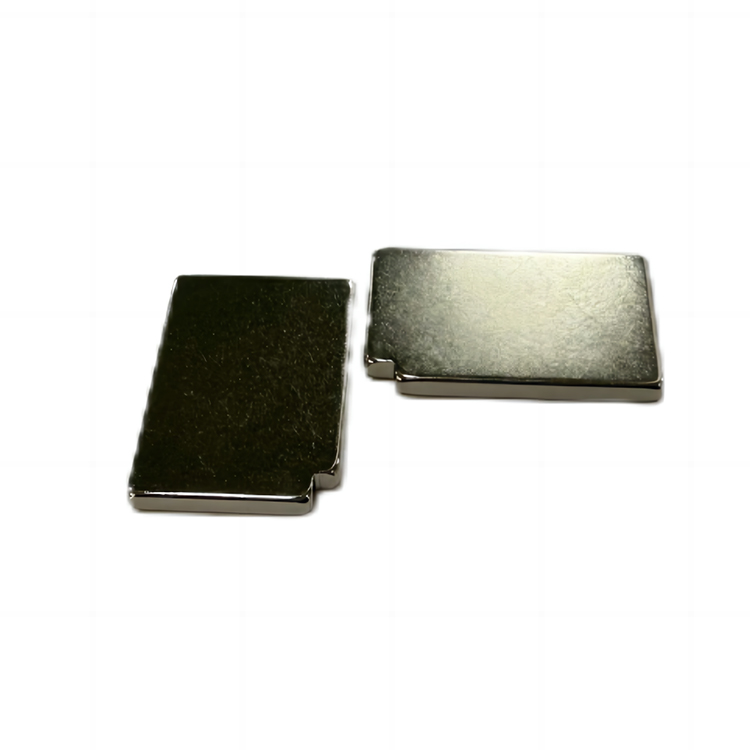

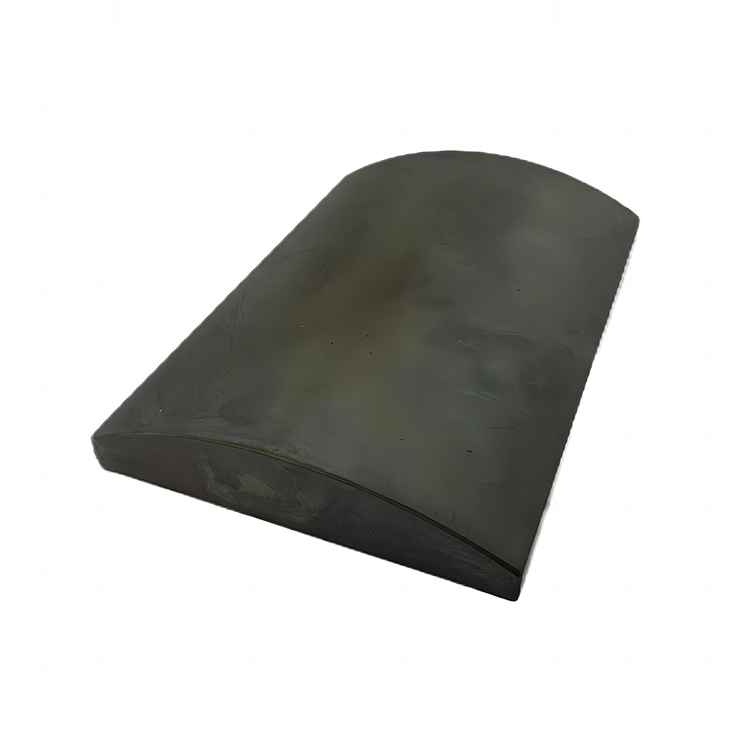

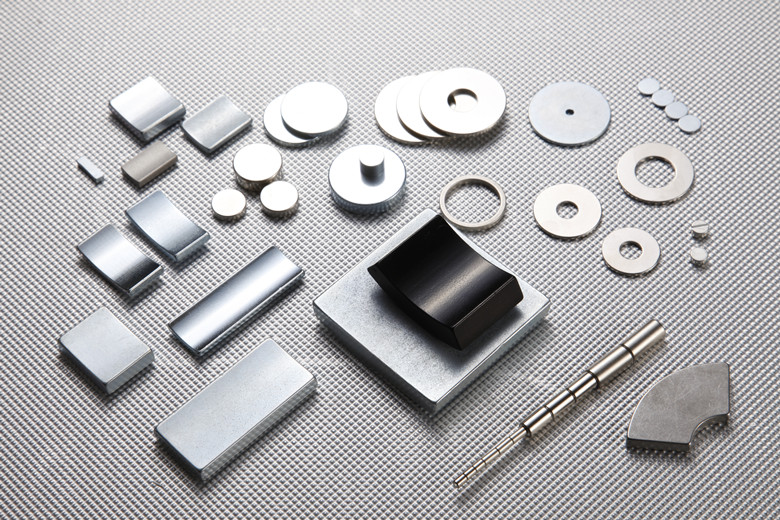

钕铁硼永磁

NdFeB是1983年以后发展起来的一种新型永磁材料,它具有极高的磁性能,广泛应用于各类永磁电机,工程机械、电声、电器及医疗器械等领域。

公司拥有VFS真空烧结炉、Alpine真空气流磨,氢破制粉及进口压机等先进设备,能生产N56、55M、55H、54SH、53UH、52EH等牌号的高性能NdFeB产品,年产量达3000吨。

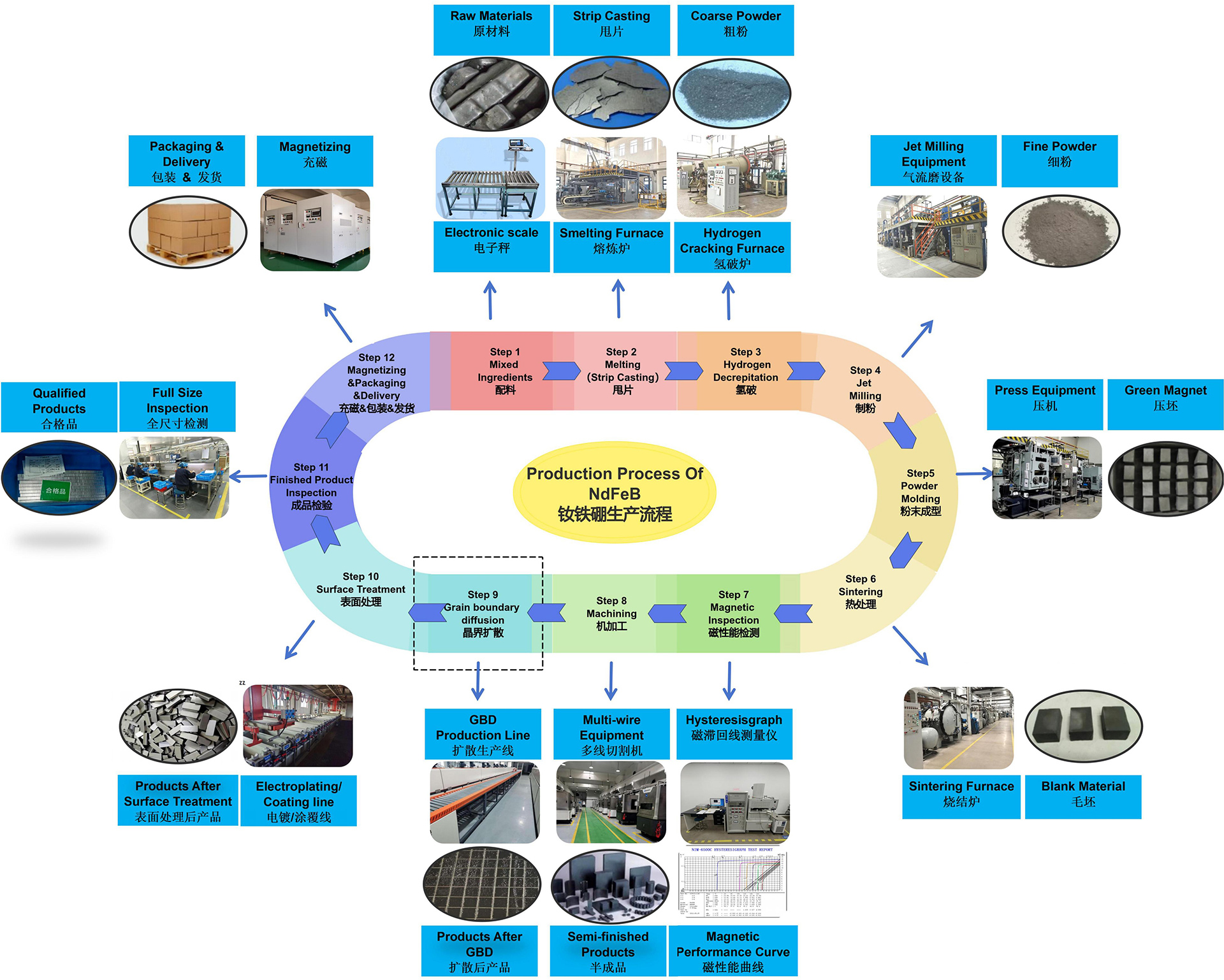

工艺流程

生产设备

牌号总览

技术优势

质量保证

产品应用

传统路线

扩散路线

熔炼炉

氢破炉

气流磨

压机

烧结炉

牌号总览

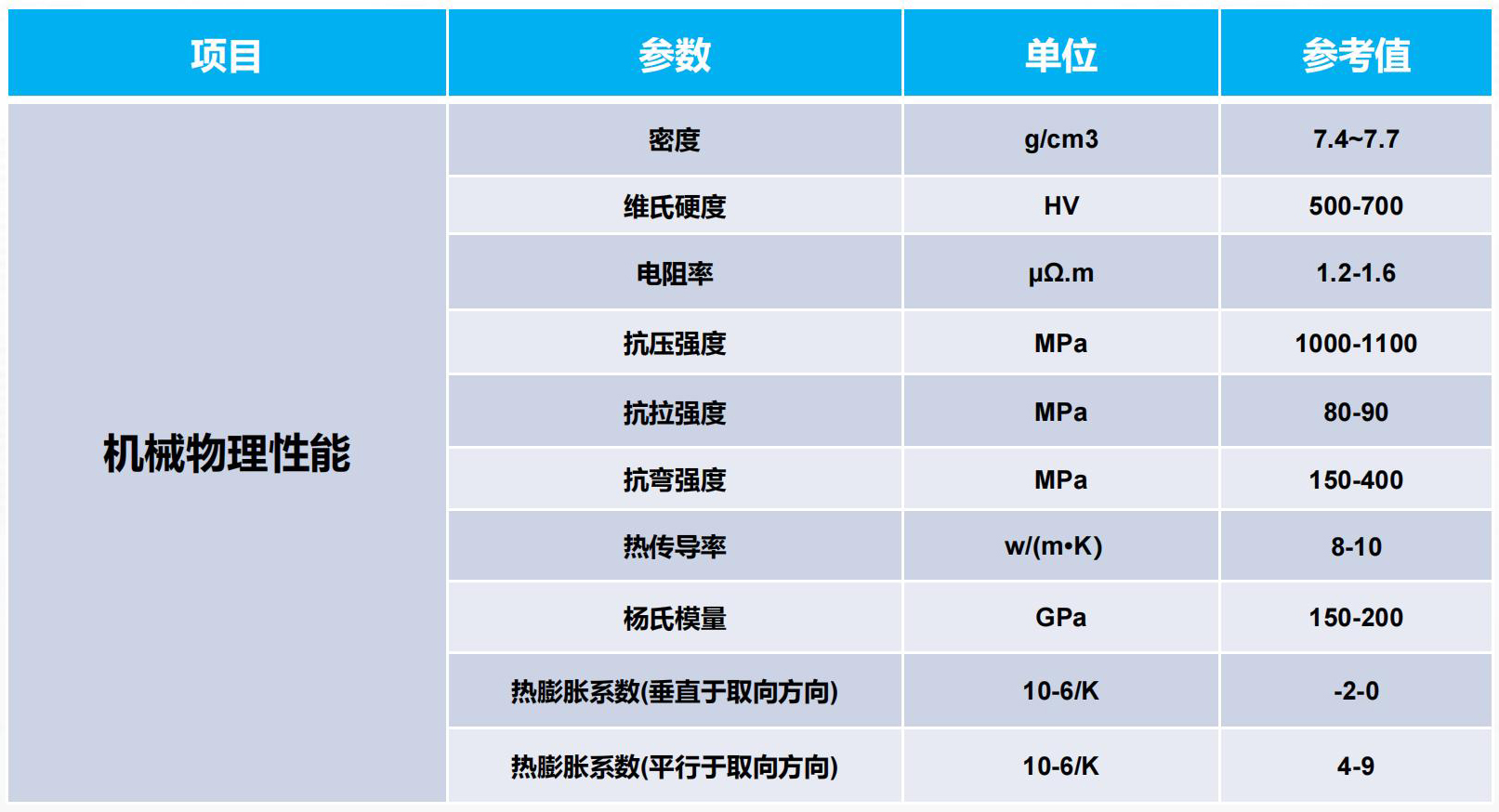

磁性能参数表

| Material 类别 |

GB/T 13560-2017 Nomenclature 规定牌号 |

Grade 牌号 |

Parameters 性 能 | ||||||

| Br 剩磁感应强度 |

Hcb 矫顽力 |

Hcj 内禀矫顽力 |

(BH)max 最大磁能积 |

∣Temperture Coefficient∣ 温度系数 |

Tw 最高工作温度 |

||||

| mT(kGs) | kA/m(kOe) | kA/m(kOe) | kJ/m3(MGOe) | ∣αBr∣ %/℃ | ∣βHcj∣ %/℃ | ℃ | |||

| N | S-NdFeB 280/96 | N35 | 1180-1230 (11.8-12.3) | ≥876 (≥11) | ≥955 (≥12) | 263-287 (33-36) | 0.10-0.124 | 0.65-0.80 | 80 |

| S-NdFeB 300/96 | N38 | 1230-1260 (12.3-12.6) | ≥899 (≥11.3) | ≥955 (≥12) | 287-310 (36-39) | 0.10-0.124 | 0.65-0.80 | 80 | |

| S-NdFeB 320/96 | N40 | 1260-1290 (12.6-12.9) | ≥912 (≥11.5) | ≥955 (≥12) | 302-326 (38-41) | 0.10-0.124 | 0.65-0.80 | 80 | |

| S-NdFeB 335/96 | N42 | 1290-1330 (12.9-13.3) | ≥923 (≥11.6) | ≥955 (≥12) | 318-342 (40-43) | 0.10-0.124 | 0.65-0.80 | 80 | |

| S-NdFeB 360/96 | N45 | 1330-1370 (13.3-13.7) | ≥931 (≥11.7) | ≥955 (≥12) | 342-366 (43-46) | 0.10-0.124 | 0.65-0.80 | 80 | |

| S-NdFeB 380/96 | N48 | 1370-1400 (13.7-14.0) | ≥939 (≥11.8) | ≥955 (≥12) | 366-390 (46-49) | 0.10-0.124 | 0.65-0.80 | 80 | |

| S-NdFeB 400/96 | N50 | 1390-1430 (13.9-14.3) | ≥947 (≥11.9) | ≥955 (≥12) | 374-406 (47-51) | 0.10-0.124 | 0.65-0.80 | 80 | |

| S-NdFeB 415/96 | N52 | 1420-1460 (14.2-14.6) | ≥947 (≥11.9) | ≥955 (≥12) | 390-414(49-52) | 0.10-0.124 | 0.65-0.80 | 80 | |

| S-NdFeB 430/96 | N54 | 1450-1490 (14.5-14.9) | ≥912 (≥11.5) | ≥955 (≥12) | 406-438 (51-55) | 0.10-0.124 | 0.65-0.80 | 80 | |

| S-NdFeB 445/96 | N56 | 1480-1520 (14.6-15.2) | ≥860 (≥10.8) | ≥876 (≥11) | 422-454 (52-57) | 0.10-0.124 | 0.65-0.80 | 70 | |

| M | S-NdFeB 280/111 | 35M | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥1114 (≥14) | 263-287 (33-36) | 0.10-0.124 | 0.60-0.75 | 100 |

| S-NdFeB 300/111 | 38M | 1230-1260 (12.3-12.6) | ≥923 (≥11.6) | ≥1114 (≥14) | 287-310 (36-39) | 0.10-0.124 | 0.60-0.75 | 100 | |

| S-NdFeB 320/111 | 40M | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥1114 (≥14) | 302-326 (38-41) | 0.10-0.124 | 0.60-0.75 | 100 | |

| S-NdFeB 335/111 | 42M | 1290-1330 (12.9-13.3) | ≥971 (≥12.2) | ≥1114 (≥14) | 318-342 (40-43) | 0.10-0.124 | 0.60-0.75 | 100 | |

| S-NdFeB 360/111 | 45M | 1330-1370 (13.3-13.7) | ≥1002 (≥12.6) | ≥1114 (≥14) | 342-366 (43-46) | 0.10-0.124 | 0.60-0.75 | 100 | |

| S-NdFeB 380/111 | 48M | 1370-1400 (13.7-14.0) | ≥1027 (≥12.9) | ≥1114 (≥14) | 366-390 (46-49) | 0.10-0.124 | 0.60-0.75 | 100 | |

| S-NdFeB 400/111 | 50M | 1390-1430 (13.9-14.3) | ≥1035 (≥13.0) | ≥1114 (≥14) | 374-406 (47-51) | 0.10-0.124 | 0.60-0.75 | 100 | |

| S-NdFeB 415/111 | 52M | 1420-1460 (14.2-14.6) | ≥995 (≥12.5) | ≥1114 (≥14) | 390-414 (49-52) | 0.10-0.124 | 0.60-0.75 | 100 | |

| S-NdFeB 430/111 | 54M | 1450-1490 (14.5-14.9) | ≥995 (≥12.5) | ≥1114 (≥13) | 406-438 (51-55) | 0.10-0.124 | 0.60-0.75 | 90 | |

| H | S-NdFeB 240/135 | 30H | 1080-1140 (10.8-11.4) | ≥827 (≥10.4) | ≥1353 (≥17) | 223-247 (28-31) | 0.09-0.120 | 0.55-0.70 | 120 |

| S-NdFeB 260/135 | 33H | 1140-1180 (11.4-11.8) | ≥860 (≥10.8) | ≥1353 (≥17) | 247-271 (31-34) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 280/135 | 35H | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥1353 (≥17) | 263-287 (33-36) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 300/135 | 38H | 1230-1260 (12.3-12.6) | ≥923 (≥11.6) | ≥1353 (≥17) | 287-310 (36-39) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 320/135 | 40H | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥1353 (≥17) | 302-326 (38-41) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 335/135 | 42H | 1290-1330 (12.9-13.3) | ≥971 (≥12.2) | ≥1353 (≥17) | 318-342 (40-43) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 360/135 | 45H | 1330-1370 (13.3-13.7) | ≥1003 (≥12.6) | ≥1353 (≥17) | 342-366 (43-46) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 380/135 | 48H | 1370-1400 (13.7-14.0) | ≥1035 (≥13.0) | ≥1353 (≥17) | 366-390 (46-49) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 400/135 | 50H | 1390-1430 (13.9-14.3) | ≥1058 (≥13.3) | ≥1353 (≥17) | 374-406 (47-51) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 415/127 | 52H | 1420-1460 (14.2-14.6) | ≥1074 (≥13.5) | ≥1353 (≥17) | 390-417 (49-52) | 0.09-0.120 | 0.55-0.70 | 120 | |

| S-NdFeB 430/127 | 54H | 1450-1490 (14.5-14.9) | ≥1074 (≥13.5) | ≥1274 (≥16) | 406-438 (51-55) | 0.09-0.120 | 0.55-0.70 | 110 | |

| SH | S-NdFeB 240/159 | 30SH | 1080-1140 (10.8-11.4) | ≥827 (≥10.4) | ≥1592 (≥20) | 223-247 (28-31) | 0.09-0.120 | 0.50-0.65 | 150 |

| S-NdFeB 260/159 | 33SH | 1140-1180 (11.4-11.8) | ≥860 (≥10.8) | ≥1592 (≥20) | 247-271 (31-34) | 0.09-0.120 | 0.50-0.65 | 150 | |

| S-NdFeB 280/159 | 35SH | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥1592 (≥20) | 263-287 (33-36) | 0.09-0.120 | 0.50-0.65 | 150 | |

| S-NdFeB 300/159 | 38SH | 1230-1260 (12.3-12.6) | ≥923 (≥11.6) | ≥1592 (≥20) | 287-310 (36-39) | 0.09-0.120 | 0.50-0.65 | 150 | |

| S-NdFeB 320/159 | 40SH | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥1592 (≥20) | 302-326 (38-41) | 0.09-0.120 | 0.50-0.65 | 150 | |

| S-NdFeB 335/159 | 42SH | 1290-1330 (12.9-13.3) | ≥971 (≥12.2) | ≥1592 (≥20) | 318-342 (40-43) | 0.09-0.120 | 0.50-0.65 | 150 | |

| S-NdFeB 360/159 | 45SH | 1330-1370 (13.3-13.7) | ≥1003 (≥12.6) | ≥1592 (≥20) | 342-366 (43-46) | 0.09-0.120 | 0.50-0.65 | 150 | |

| S-NdFeB 380/159 | 48SH | 1370-1400 (13.7-14.0) | ≥1035 (≥13.0) | ≥1592 (≥20) | 366-390 (46-49) | 0.09-0.120 | 0.50-0.65 | 150 | |

| S-NdFeB 400/159 | 50SH | 1390-1430 (13.9-14.3) | ≥1058 (≥13.3) | ≥1592 (≥20) | 374-406 (47-51) | 0.09-0.120 | 0.50-0.65 | 150 | |

| S-NdFeB 415/159 | 52SH | 1420-1460 (14.2-14.6) | ≥1074 (≥13.5) | ≥1512 (≥19) | 390-414 (49-52) | 0.09-0.120 | 0.50-0.65 | 140 | |

| UH | S-NdFeB 220/199 | 28UH | 1040-1090 (10.4-10.9) | ≥780 (≥9.8) | ≥1990 (≥25) | 207-231 (26-29) | 0.09-0.110 | 0.50-0.60 | 180 |

| S-NdFeB 240/199 | 30UH | 1080-1140 (10.8-11.4) | ≥827 (≥10.4) | ≥1990 (≥25) | 223-247 (28-31) | 0.09-0.110 | 0.50-0.60 | 180 | |

| S-NdFeB 260/199 | 33UH | 1140-1180 (11.4-11.8) | ≥827 (≥10.4) | ≥1990 (≥25) | 247-271 (31-34) | 0.09-0.110 | 0.50-0.60 | 180 | |

| S-NdFeB 280/199 | 35UH | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥1990 (≥25) | 263-287 (33-36) | 0.09-0.110 | 0.50-0.60 | 180 | |

| S-NdFeB 300/199 | 38UH | 1230-1260 (12.3-12.6) | ≥923 (≥11.6) | ≥1990 (≥25) | 287-310 (36-39) | 0.09-0.110 | 0.50-0.60 | 180 | |

| S-NdFeB 320/199 | 40UH | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥1990 (≥25) | 302-326 (38-41) | 0.09-0.110 | 0.50-0.60 | 180 | |

| S-NdFeB 335/199 | 42UH | 1290-1330 (12.9-13.3) | ≥971 (≥12.2) | ≥1990 (≥25) | 318-342 (40-43) | 0.09-0.110 | 0.50-0.60 | 180 | |

| S-NdFeB 360/199 | 45UH | 1330-1370 (13.3-13.7) | ≥1003 (≥12.6) | ≥1990 (≥25) | 342-366 (43-46) | 0.09-0.110 | 0.50-0.60 | 180 | |

| S-NdFeB 380/199 | 48UH | 1360-1400 (13.6-14.0) | ≥1035 (≥13.0) | ≥1910 (≥24) | 358-390 (45-49) | 0.09-0.110 | 0.50-0.60 | 170 | |

| EH | S-NdFeB 220/239 | 28EH | 1040-1090 (10.4-10.9) | ≥780 (≥9.8) | ≥2388 (≥30) | 207-231 (26-29) | 0.09-0.110 | 0.45-0.55 | 200 |

| S-NdFeB 240/239 | 30EH | 1080-1140 (10.8-11.4) | ≥827 (≥10.4) | ≥2388 (≥30) | 223-247 (28-31) | 0.09-0.110 | 0.45-0.55 | 200 | |

| S-NdFeB 260/239 | 33EH | 1140-1180 (11.4-11.8) | ≥860 (≥10.8) | ≥2388 (≥30) | 247-271 (31-34) | 0.09-0.110 | 0.45-0.55 | 200 | |

| S-NdFeB 280/239 | 35EH | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥2388 (≥30) | 263-287 (33-36) | 0.09-0.110 | 0.45-0.55 | 200 | |

| S-NdFeB 300/239 | 38EH | 1230-1260 (12.3-12.6) | ≥923 (≥11.6) | ≥2388 (≥30) | 287-310 (36-39) | 0.09-0.110 | 0.45-0.55 | 200 | |

| S-NdFeB 320/239 | 40EH | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥2388 (≥30) | 302-326 (38-41) | 0.09-0.110 | 0.45-0.55 | 200 | |

| S-NdFeB 335/239 | 42EH | 1290-1330 (12.9-13.3) | ≥971 (≥12.2) | ≥2388 (≥30) | 318-342 (40-43) | 0.09-0.110 | 0.45-0.55 | 200 | |

| S-NdFeB 360/231 | 45EH | 1330-1370 (13.3-13.7) | ≥1003 (≥12.6) | ≥2308 (≥29) | 342-366 (43-46) | 0.09-0.110 | 0.45-0.55 | 190 | |

| TH | S-NdFeB 220/279 | 28TH | 1040-1090 (10.4-10.9) | ≥780 (≥9.8) | ≥2786 (≥35) | 207-231 (26-29) | 0.09-0.110 | 0.40-0.50 | 230 |

| S-NdFeB 240/279 | 30TH | 1080-1140 (10.8-11.4) | ≥827 (≥10.4) | ≥2786 (≥35) | 223-247 (28-31) | 0.09-0.110 | 0.40-0.50 | 230 | |

| S-NdFeB 260/279 | 33TH | 1140-1180 (11.4-11.8) | ≥860 (≥10.8) | ≥2786 (≥35) | 247-271 (31-34) | 0.09-0.110 | 0.40-0.50 | 230 | |

| S-NdFeB 280/279 | 35TH | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥2786 (≥35) | 263-287 (33-36) | 0.09-0.110 | 0.40-0.50 | 230 | |

| S-NdFeB 300/279 | 38TH | 1230-1260 (12.3-12.6) | ≥923 (≥11.6) | ≥2786 (≥35) | 287-310 (36-39) | 0.09-0.110 | 0.40-0.50 | 230 | |

| S-NdFeB 320/279 | 40TH | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥2786 (≥35) | 302-326 (38-41) | 0.09-0.110 | 0.40-0.50 | 230 | |

| S-NdFeB 335/270 | 42TH | 1290-1330 (12.9-13.3) | ≥971 (≥12.2) | ≥2706 (≥34) | 318-342 (40-43) | 0.09-0.110 | 0.40-0.50 | 220 | |

牌号系列

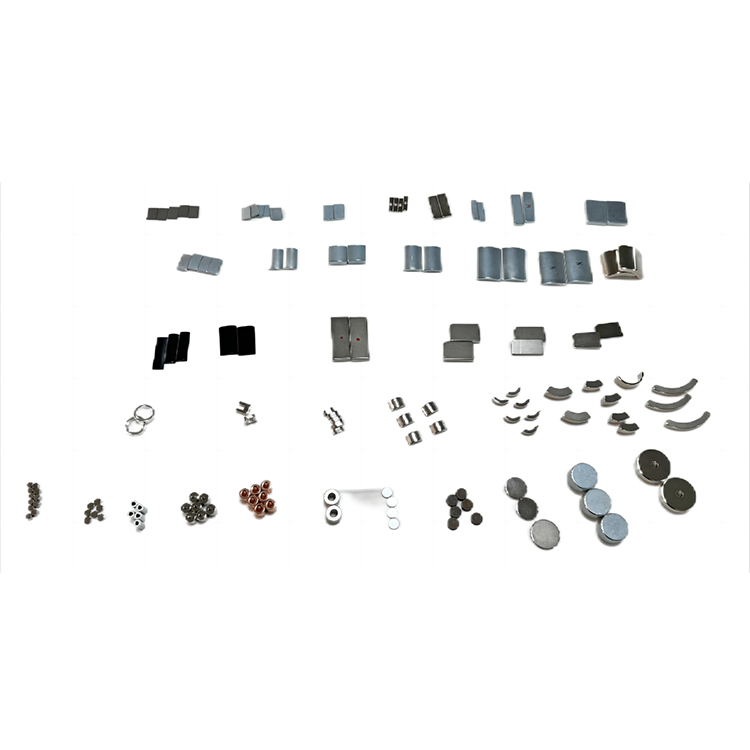

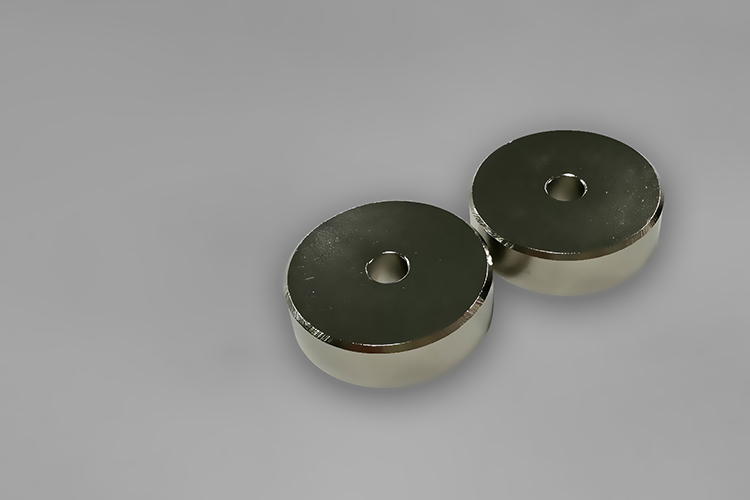

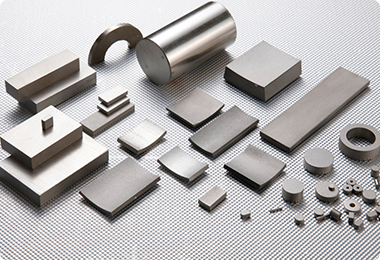

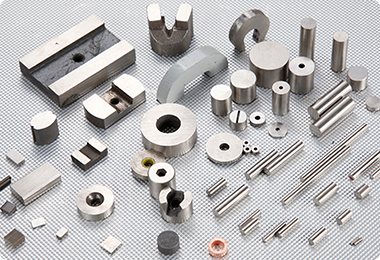

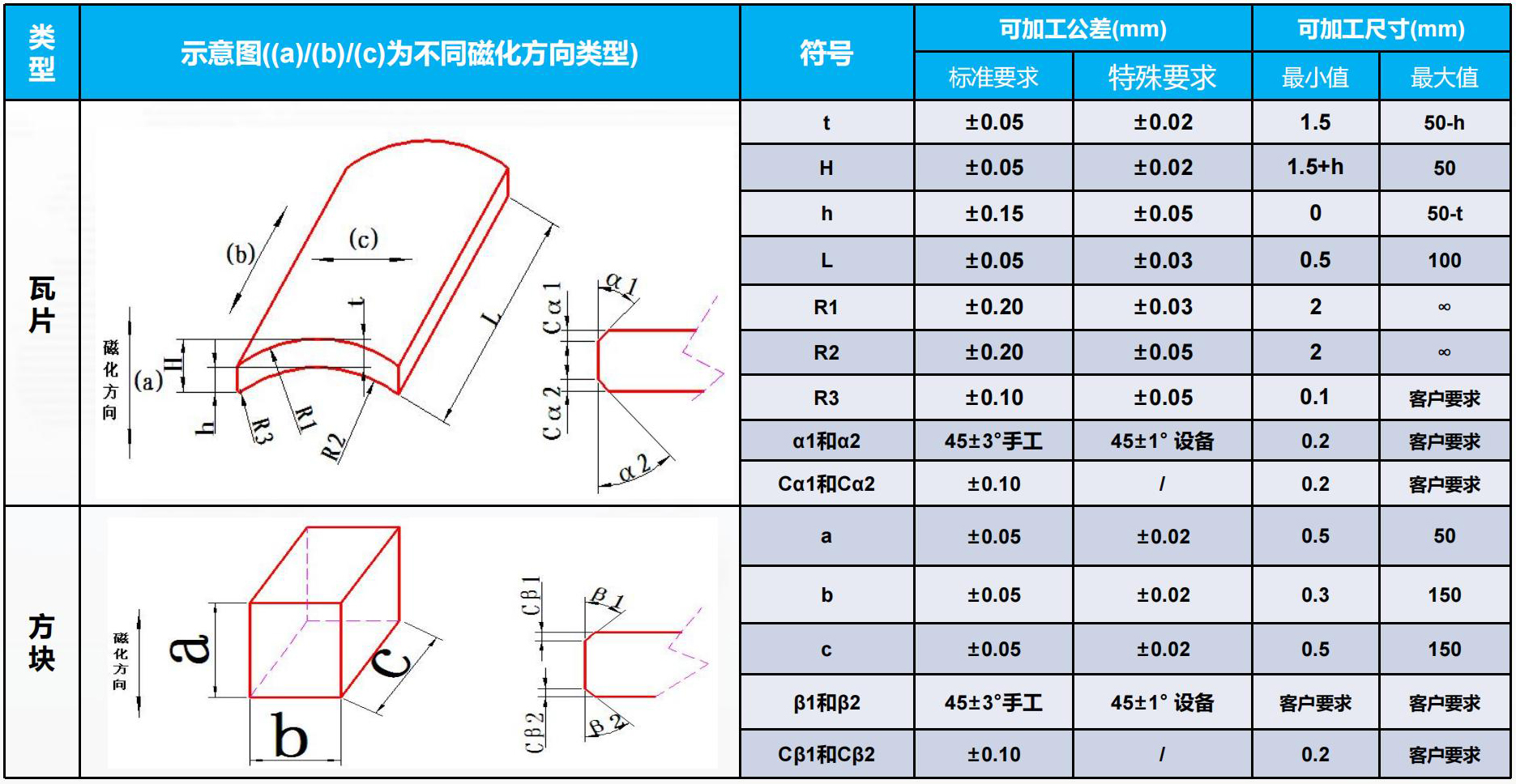

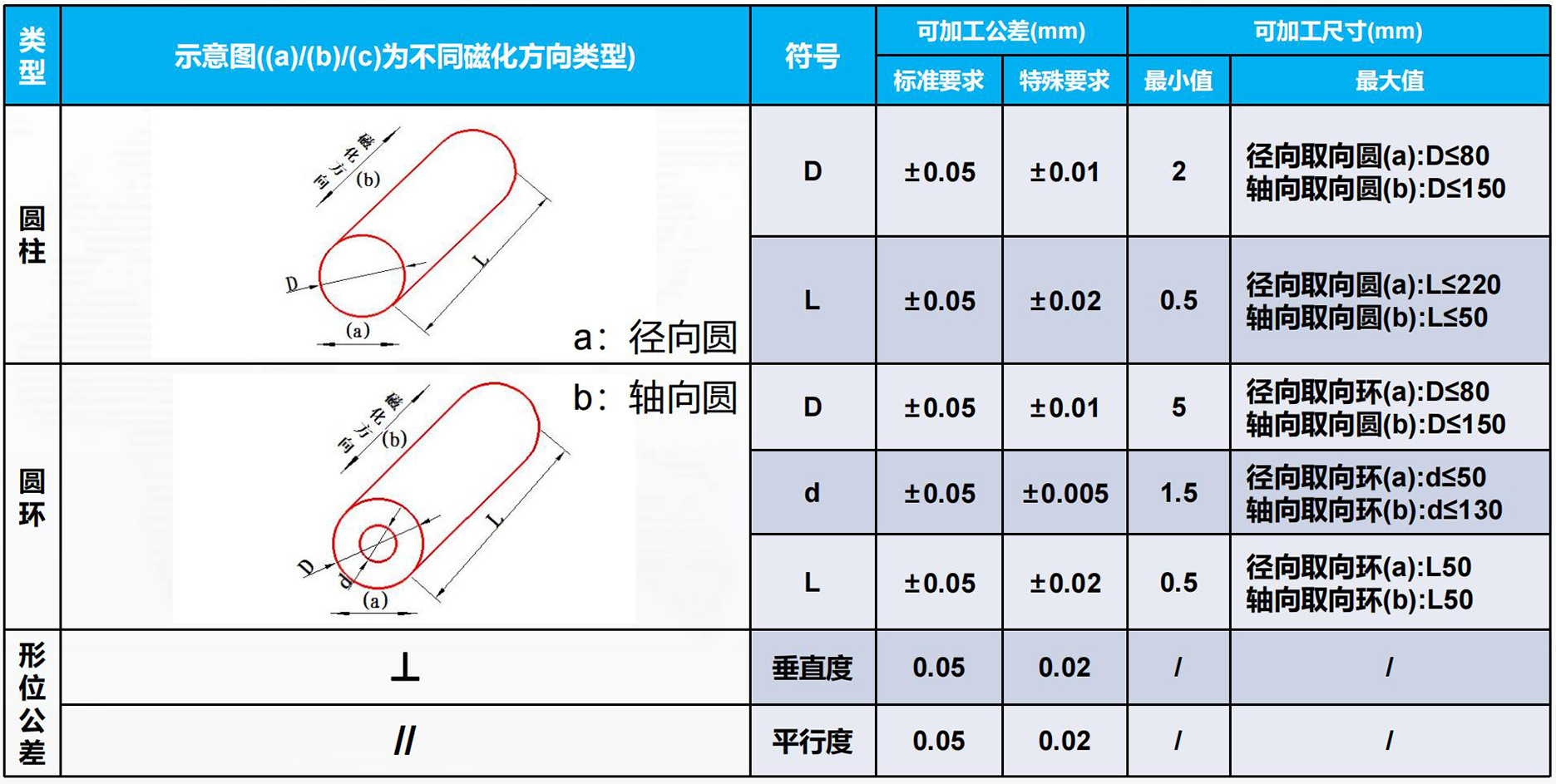

加工能力

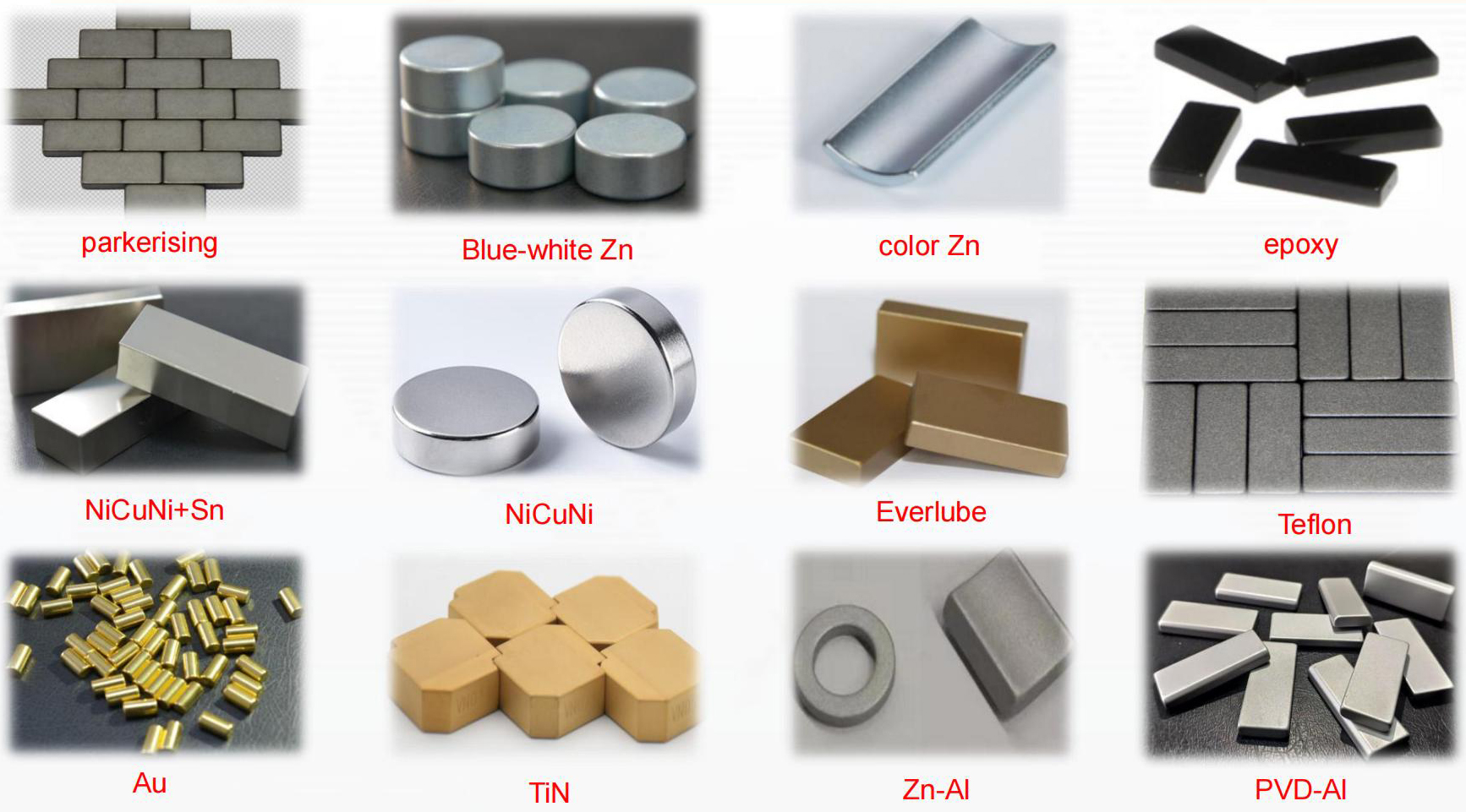

电镀镀层

体证书

140001环境管理证书 英文

IATF16949证书 中文

IATF16949证书 英文

ISO9001证书 中文

ISO9001证书 英文

振泽知识产权证书

检测能力

EF14磁矩

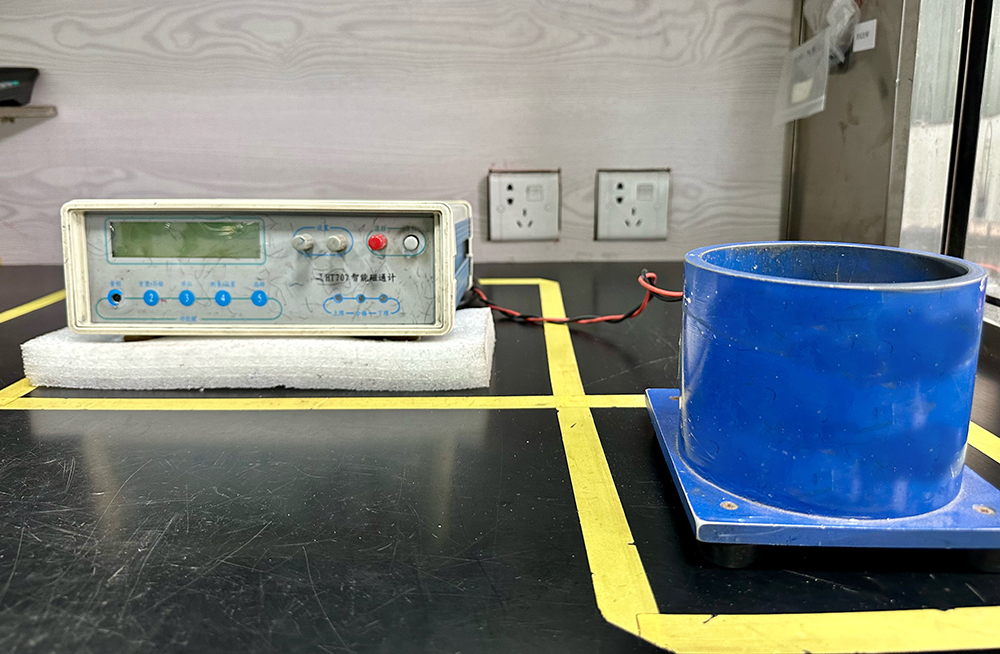

HT707测试仪

ICP 光普分析仪

尺寸分选机

磁偏角

磁滞回线测量仪

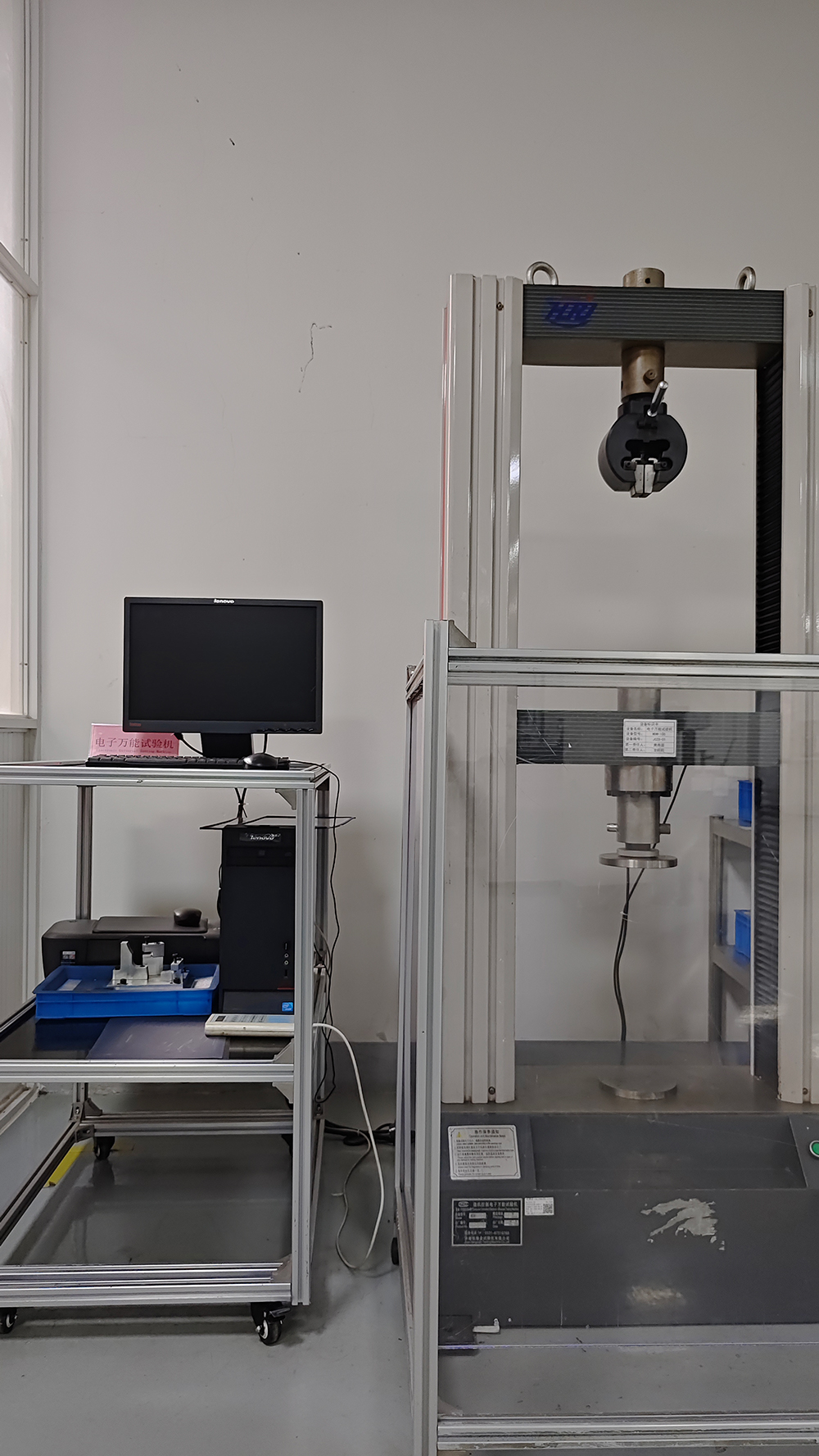

电子万能试验机

镀层测厚仪

高度加速寿命试验箱

冷热冲击试验箱

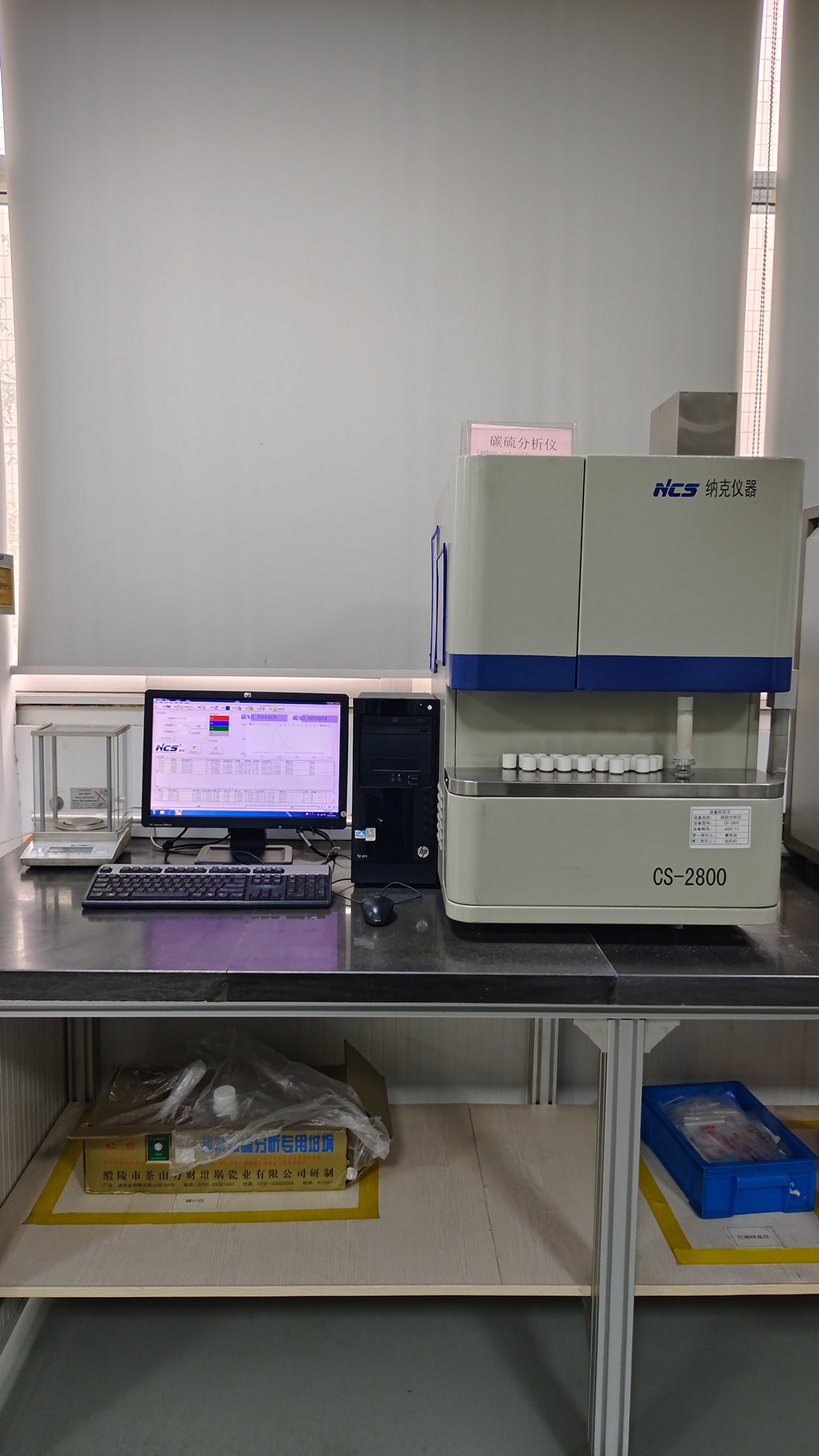

碳硫分析仪

投影仪

显微镜

盐雾

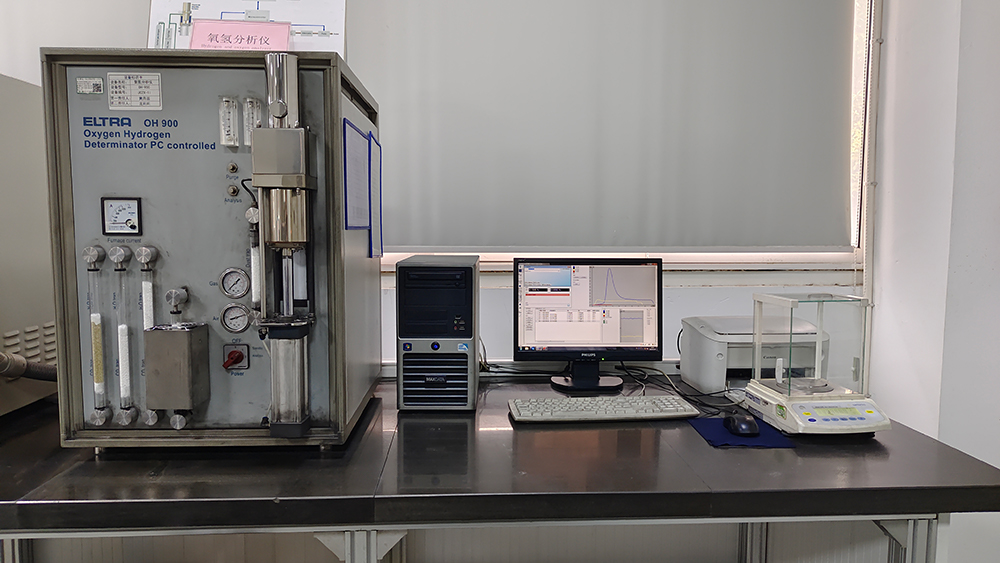

氧氢分析仪

产品展示